Supply Chain Management

The Skylark Group has established standards for quality and hygiene management, and made its basic policy to thoroughly manage various foreseeable risks in all processes, from procurement of ingredients to processing, distribution, preparation and provision to customers.

We constantly incorporate the latest scientific insights from supervisory authorities, various inspection organizations and food industry bodies to build and operate a realistic and supremely effective quality assurance system, and pursue safety and security for our customers from all possible angles.

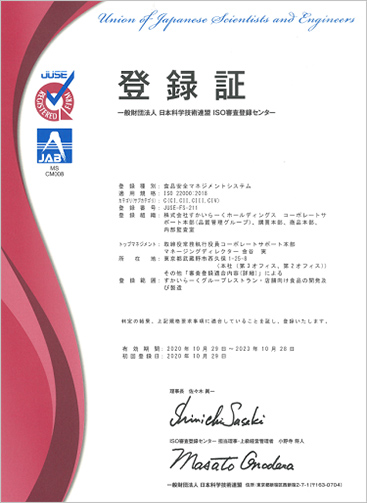

Acquisition of ISO 22000 Certification

Skylark has acquired certification under the ISO 22000 international food safety management standard. In addition to all ten of our central kitchens in Japan, we have also acquired certification for purchasing departments responsible for procurement, menu development departments, quality control departments, and internal audit departments

Procurement

Establishing a Traceability System

Based on the Ministry of Agriculture, Forestry and Fisheries (MAFF) guidelines on the labeling of production locations for restaurants, etc., Skylark publishes the production areas for its main raw ingredients including meats and seafood for its Japanese-style restaurants.

Additionally, by managing manufacturing information on our products by lot number, we have established a traceability system that allows us to go back to the time of shipment in the event of any quality-related problems.

Audits of Suppliers

When procuring ingredients, we inspect local factories and processes in accordance with our purchasing management regulations. We check hygiene management systems for each process at supplier locations based on the HACCP*1 approach and purchase ingredients only from suppliers that meet our trading standards.

*1 HACCP is a hygiene management approach that stands for Hazard Analysis and Critical Control Points

Inspection

Thorough Inspections by Skylark’s Quality Management Group

The Quality Management Group, which manages food safety, conducts bacterial tests at its own hygiene inspection laboratory before the introduction of new products, regardless of whether they are proprietary or purchased products. In this way, we ensure that only ingredients that have passed inspections based on our internal criteria are delivered to our restaurants and stores nationwide.

Even after distribution has begun, we conduct periodic sampling inspections at eight hygiene inspection laboratories around Japan, covering products sent to restaurants to foods immediately before they are served to customers, in order to confirm safety at each stage of the supply chain, from raw ingredients to processing and serving. In bacterial testing, inspection items and reference values are established for each item. When a test result exceeds the reference value, prompt measures are taken, such as prohibition of use or discontinuation.

By conducting hygiene patrols at each of our restaurants and stores in conjunction with operational audit guidance team, we perform thorough checks and provide guidance on more than 50 checklist items relating to hygiene, including food management and the state of cleaning.

In addition, checking processes and the state of hygiene management at our central kitchens through unannounced monthly checks based on ISO 22000 concepts and reviewing the results also improves employee training. The number of samples tested by the Group each year is about 100,000, which is a top-class level for the restaurant industry.

From March 2022, the Skylark Group started conducting in-house residual pesticide inspections to further ensure food safety. In addition to checking the status of pesticide management at farm fields, we inspect raw vegetables used and products manufactured in the central kitchen to ensure the safety of the menus we provide.

Production

ISO 22000 Based Hygiene Management System

Our central kitchens, where ingredients undergo primary process and are then distributed, received ISO 22000 certification after establishing a hygiene management system in line with ISO 22000. We have also installed cameras to ensure that employees wash their hands, check the health of all employees, including household members, etc. to ensure that viruses are not brought into the central kitchen.

Logistics

Our Transportation System Keeps Food Fresh

In order to deliver food in a fresh state, Skylark has created a system for delivering products primarily from its central kitchens (8 locations) to its restaurants in all 47 prefectures in Japan.

In order to maintain the ideal temperature range depending on the ingredients, we inject the necessary amount of carbon dioxide gas to use based on the temperature each day and the distance to the restaurant into our cooling boxes accordingly before delivery.

Preparation and Service at Stores

Thorough Food/Ingredient Management

We focus on food management and cooking/food preparation with uniform quality at our stores throughout Japan based on hygiene management methods incorporating the HACCP approach.

We provide manuals that summarize procedures and key points on hygiene management in an easy-to-understand manner, so that staff can manage them appropriately, and have established a system that allows us to provide delicious food with safety and peace of mind, through regular guidance on food preparation.

Allergen and Nutritional Information Labelling

We constantly update allergen and nutritional information related to seven specific raw ingredients to enable customers with food allergies and those who are limiting their calorie count or salt intake to enjoy dining with peace of mind.

We have established procedures and take great care when serving low-allergen menu items at our restaurants to ensure that no mistakes are made, and to prevent contamination by different ingredients. All allergen and nutritional information requests are handled on an individual basis.

Quality Management Training

We have established food hygiene committees for each brand and each central kitchen to improve food hygiene knowledge through regular committee meetings. Quality control departments conduct hygiene patrols at each store and central kitchen to check managers who play a central role in the training system, to ensure uniformity of knowledge levels and to maintain and improve it. The quality control departments also obtain the most recent professional knowledge from outside the company to improve quality management at the Company.

For our suppliers, our purchasing staff and staff from quality control departments conduct inspections during which they are accompanied, depending on the characteristics of the food ingredients, to provide guidance for improvement.