Policy and Approach

With regard to food ingredients, Skylark Group has established a Quality Charter to respond to all foreseeable food-related risks in every supply chain process, from procurement of raw ingredients through processing, distribution, storage, and provision of food to customers.

The Group also performs precise, swift, unannounced inspections of all processes, examining traceability and hygienic handling, anticipating hazards such as bacterial and viral food poisoning, allergies, and contamination by agrichemicals and foreign objects.

We constantly incorporate the latest scientific insights from supervisory authorities, various inspection organizations and food industry bodies to build and operate a realistic and supremely effective quality assurance system, and pursue safety and security for our customers from all possible angles.

Examples of Action

Education on Food Safety

We have established food hygiene committees for each brand and central kitchens to improve knowledge of food hygiene through regular committee meetings. The quality control department conducts hygiene patrols for managers at each store and central kitchen that play a central role in the education system, in an effort to equalize, maintain and improve the level of knowledge. Each store and central kitchen is provided with a list of priority food hygiene issues and training at that time.

For hygiene education at stores, in addition to manuals, we provide educational tools in video format, and we have created an environment where part-time employees can learn from anywhere. For the education and training of non-Japanese employees, we take measures to translate necessary information into foreign languages.

The quality control department obtains the latest specialized knowledge from external sources and uses it to improve the level of quality within the Group. In addition to training from the quality control department for those in charge of purchasing on how to improve their level of knowledge, purchasing and quality control department personnel participate in inspections and provide specific guidance for business partners (suppliers) to improve quality, according to the characteristics of food ingredients.

Providing Quality-related Information to Customers

In providing information on the quality of food products to customers, we follow the Labling Guidelines on Promotional Materials and practice lawful and appropriate labeling in our menu books and other promotional tools.

All basic information on ingredients, such as allergens, production locations and additives are managed centrally by a dedicated system, and information from the system is used in processes such as menu development, recipe production, manufacturing processes, and display of promotional materials, in our efforts to display information correctly.

The contents of labels are displayed after prior checks by the quality control department and, where necessary, the legal department.

Departments responsible for creating promotional tools receive regular training on labeling, including the Food Labeling Act and the Act against Unjustifiable Premiums and Misleading Representations, in an effort to maintain and improve labeling skills.

The internal audit department is responsible for auditing whether each step of the flow from the creation of promotional materials to checking and the actual display of materials is conducted appropriately, in accordance with regulations and manuals.

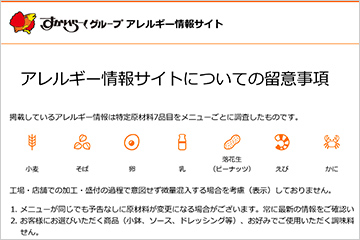

| Allergies |

To enable customers to enjoy meals with peace of mind, we disclose allergy information on seven major allergens: egg, milk, wheat, shrimp, crab, buckwheat and peanuts. We also manage information on 21 other allergens and provide the latest information whenever an inquiry is made. |

| Production Locations |

Based on the Ministry of Agriculture, Forestry and Fisheries guidelines on the publishing of production locations for restaurants, Skylark discloses the production areas for its main raw ingredients including meats. |

| Traceability |

We disclose rice production area information based on the Rice Traceability Act.

Some brands also use the cattle traceability system and post individual identification numbers for domestic cattle to provide information to customers. We also manage information in addition to that which is stipulated by laws and regulations so that necessary information can be traced.

|

Certifications Acquired

Food Safety Management System Certification (ISO22000)

Skylark has obtained certification under the ISO22000 international food safety management standard. In addition to all ten of our central kitchens in Japan, we have also acquired certification for purchasing departments responsible for procurement, menu development departments, quality control departments, and internal audit departments.

By adding purchasing and menu development departments to the list of departments covered by this certification, we can confirm the validity and appropriateness of food safety management systems by our suppliers and food preparation procedures at our restaurants. In this way, we are building a food management system that is integrated with our supply chain.

(Click to Enlarge)

| Registration Type |

Food Safety Management System |

| Applicable Standards |

ISO22000: 2018 |

Category

(Sub-category) |

C (CI,CII,CIII,CIV) |

| Registration Number |

JUSE-FS-211 |

| Registered Organization |

Quality Control Group, Supply Chain Purchasing Group, Menu Development, Marketing and Production Division, Internal Audit Office

SKYLARK HOLDINGS CO., LTD. |

| Top Management |

Ichiro Takei,

Executive Officer

Managing Director of Administrative Division |

| Address |

1-25-8 Nishikubo, Musashino-shi, Tokyo (Head office buildings), and other locations specified in the list of registered facilities |

| Registered Range |

Development and manufacturing of restaurant food products for Skylark Group Restaurants, and food products sold through e-commerce |

| This Certification Is Valid From |

October 29, 2019 - October 28, 2023 |

| Date of Initial Certification |

October 29, 2004 |

| Reissuing Date |

November 24, 2021 |