Policy and Approach

To fulfill social responsibilities through our business operations, Skylark Group has established purchasing management regulations, through which we ensure the purchase of safe, high-quality ingredients and respond to social issues, in addition to complying with laws and regulations.

In addition, the "Group Sustainability Committee" meets as needed and continues to formulate policies, targets, and measures related to responsible procurement.

In selecting suppliers, we prioritize those that are making meaningful progress in environmental, social, and governance (ESG) practices.

Our evaluation goes beyond financial reliability and product quality, and includes a range of ESG-related factors—such as employee management (including occupational health and safety), respect for human rights (e.g., the elimination of child labor, forced labor, discrimination, and harassment; freedom of association; collective bargaining; and the prevention of excessive working hours), environmental responsibility (e.g., energy use, climate change response, pollution prevention, waste and water management, biodiversity, food loss reduction, and responsible use of resources), and ethical compliance (e.g., anti-corruption, management of conflicts of interest, and prevention of anti-competitive behavior). We also take into account the supplier’s approach to other forms of antisocial conduct.

We also ask suppliers for their understanding and cooperation in providing information relating to our environmental policies, communication with our company and training activities, to engage in joint corporate activities and aim for coexistence and co-prosperity of society and the environment together.

Currently, we have suppliers in 40 countries around the world. We do not judge based on the laws, customs and current situation of each region, but on whether there are any significant discrepancies in light of applicable Japanese laws. We strive for responsible procurement by enforcing a strict policy of not initiating transactions if there is any problem.

1. Supplier Selection

When selecting new suppliers, we conduct the following due diligence on all suppliers prior to the start of transactions in accordance with our "Detailed Rules for Sustainable Procurement Management" for the purpose of risk assessment of environmental and social issues.

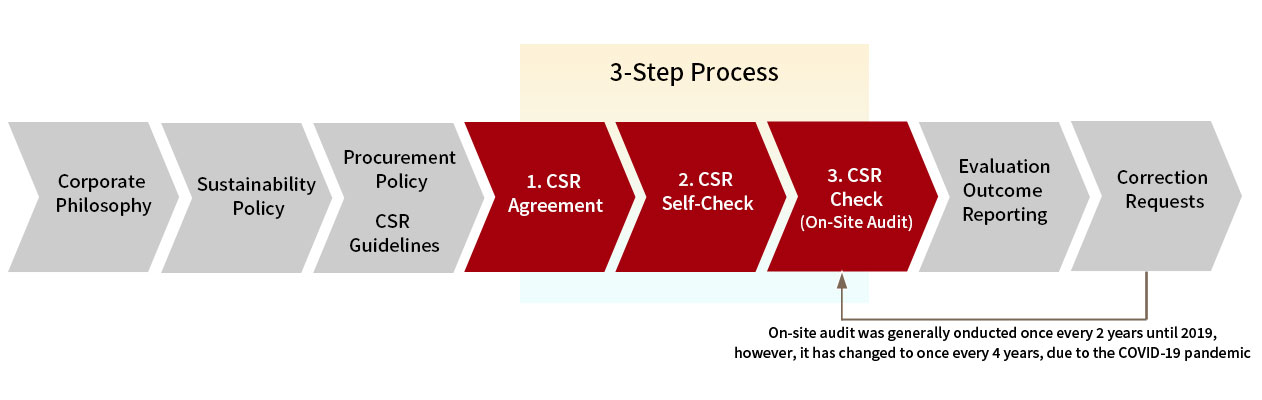

Due Diligence Process

- CSR Agreement: Process to request suppliers to agree to our procurement guidelines before starting business with us.

- CSR Self-check: Process to assess suppliers' understanding of CSR requirements by asking them to complete a self-assessment.

- CSR Check: Process where our buyers visit supplier factories directly and assess current conditions in collaboration with suppliers, and utilize the results to improvement activities.

※ This also applies to secondary suppliers.

※ Supplier evaluations are conducted with reference to the methodology developed by the Supply Chain Subcommittee of the Global Compact Network Japan.

Scope of Coverage

2. Supplier Monitoring and Audit

- Both in Japan and overseas, monitoring and audit on all suppliers are conducted on a regular basis (once every two years, with an annual cycle as the target), regardless of the scale of the transaction. Through this monitoring and auditing, we identify suppliers with high risk of environmental and social problems, and provide support to all suppliers by sharing information and providing guidance for improvement through feedback.

- Under the supervision of the Board of Directors, the status and details of monitoring and auditing are reported quarterly and promoted by the Group Sustainability Committee, which is chaired by the President and Representative Director in charge and consists of the Chairman and Representative Director, all executive officers, and presidents of group companies as members.

- Since FY2022, in addition to the traditional monitoring of food and product quality and safety, we have been monitoring, auditing, and providing training guidance on social issues such as human rights, labor practices, and fair corporate activities based on our Procurement Policy and Anti-Bribery Policy, and on our basic stance toward environmental initiatives based on our Environmental Policy.

- We meet with suppliers at least once a year to communicate and provide guidance on environmental and social issues based on our "CSR Guidelines".

- All suppliers' manufacturing factories are regularly visited by our buyers to confirm, evaluate and provide guide whether their food safety processes are operating as intended, not just at the start of a transaction. Results are also documented and stored, shared with suppliers, and linked to improvement activities.

- Quantitative confirmations of changes in transaction amounts and results of food sanitation inspections for each supplier are carried out after sharing information with the Finance Department and Quality Control Department.

- In addition to food hygiene inspections, audits and evaluations—including confirmation of requirements for occupational health and environmental conservation—are conducted after on-site inspections.

- Buyers collect as much information as possible on employee management, care and consideration for human rights and pollution control measures at suppliers, as well as the situation with regard to antisocial behaviors.

- In the case of overseas suppliers, we do not judge based only on local laws, customs and circumstances, but by evaluation and judgment in light of Japanese laws and customs. Matters are reported to the manager of the relevant department at headquarters and evaluations are carried out.

- In addition to re-evaluating risks of social problems at existing suppliers through daily information gathering and periodic factory checks, we also pay attention to industry information on each supplier and evaluate their reliability as corporate entities.

- In FY2024, there were no nonconformities with our "Environmental Policy", "Procurement Policy" and "Anti-Bribery Policy" as required by our company as in FY2023 and FY2022. In the event of nonconformity or serious violation, we will confirm the facts and request the supplier to take corrective actions. If necessary, we or our appointed experts will visit the site and conduct an investigation. If the supplier does not take corrective action within the required period of time, we will take action, including a termination of the transaction.

※Number of key primary suppliers: Number of suppliers identified as having ESG impacts or high business relevance and risk.

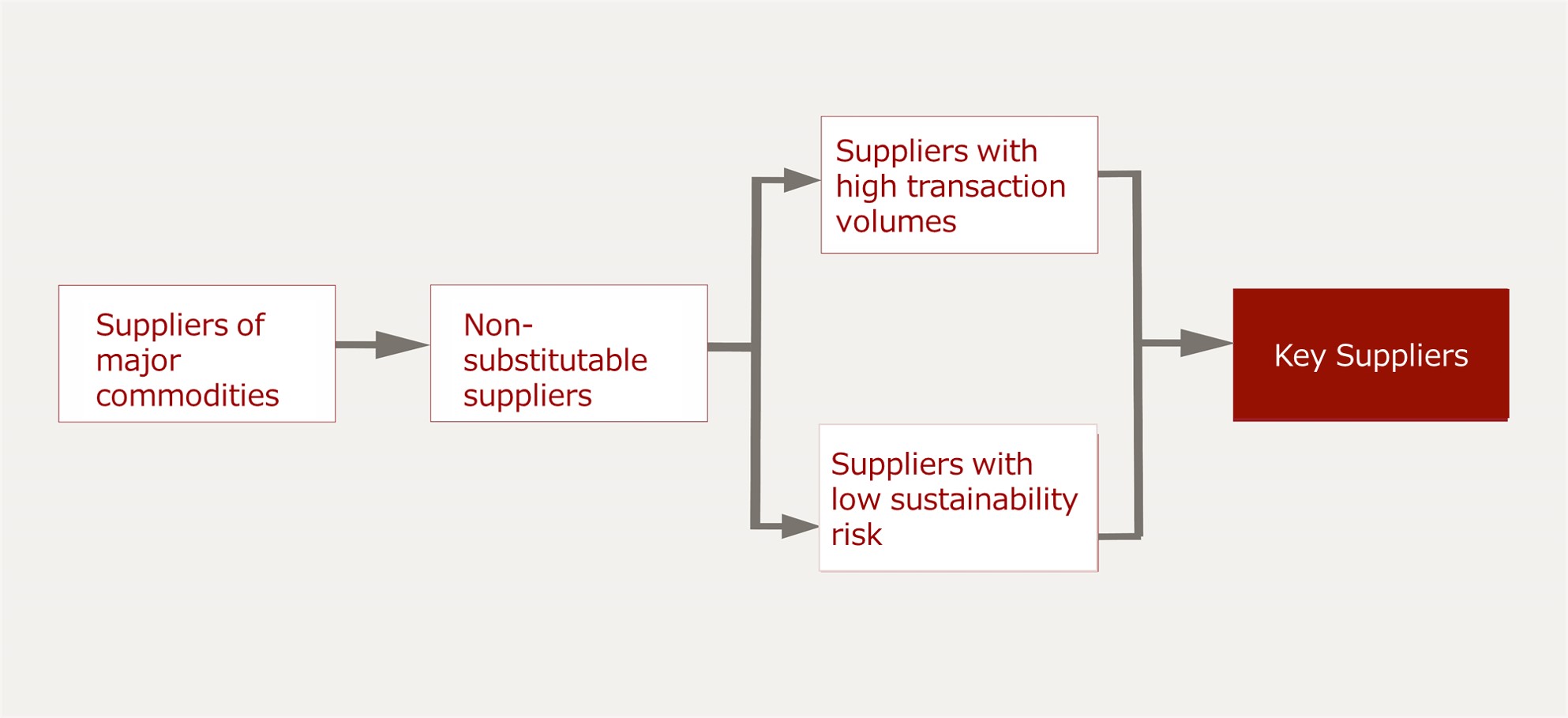

Key Suppliers

Suppliers identified as having ESG impacts or high business relevance and risk.

| Item

|

Definition

|

| Suppliers of major commodities |

Products with annual value of 1 billion yen or more and suppliers handling 500 million yen or more |

| Non-substitutable suppliers |

Purchases of 500 million yen or more per item and PB items |

| Suppliers with high transaction volumes |

Business partners with high transaction volume (transaction value of 1 billion yen or more) |

| Suppliers with low sustainability risk |

CSR check score of 95 or higher. Suppliers with excellent environmental, social, and governance ESG initiatives, with no identified risks related to country or region, sector, or product category(※). |

(※)

Country/region risk: Risk of adverse ESG impacts related to national or regional political, economic, environmental, regulatory, or other conditions

Sector risk: Risk of adverse ESG impacts related to labor conditions, emissions, pollution, and other conditions

Product risk: Risk of adverse ESG impacts related to commodity supply chain structure, labor conditions, energy consumption, emissions, and pollution

Specific Process

3. Education and Training for Skylark Buyers

- Joint training sessions are held twice a year for all buyers to acquire and update knowledge in line with revisions of laws and regulations and changes in social conditions, and through the guidance of the in-house quality control department, education is provided.

- We also conduct on-the-job verification through "training programs accompanying" existing buyers' quality control staff when they visit suppliers in Japan and overseas.

- At the time of buyer's arrival, "Basic Knowledge Acquisition" including factory and sanitation center training is conducted based on a prescribed curriculum.

- Procurement Department employees comply with laws and regulations, industry agreements and norms, strive to gather information from the relevant ministries, agencies, industry bodies and suppliers; share with related departments within the company, including the Quality Control Department; and establish and revise management methods.

- We are fully aware that our contracts with suppliers are based on "fair, reasonable, and transparent" business relationships and that we are in a "superior position" in the eyes of society, and we strive to avoid any misunderstanding that we are engaged in "unfair" business relationships.

- Training for Skylark buyers on environmental and social issues is conducted at least twice a year.

4. Support for Initiatives and Cooperation with External Organizations

- Skylark actively collects information on advanced efforts from initiatives and consortiums both in Japan and other countries. We also participate in both regular and irregular seminars and study groups and actively disseminate information through exchanges of opinions. Through activities in cooperation with suppliers and companies in other industries, we work to further reduce the Group's environmental impact, resolve social issues, and work toward the creation of a sustainable society.

(Initiatives to reduce environmental impact and tackle societal issues)

- ISO 20400, the international standard for sustainable procurement

Foodstuff procurement operations in 18 categories under the jurisdiction of the Foodstuff Purchasing Group, and other operations as per "Details of Compliance with Certification/Registration (Details)".

- United Nations Global Compact, and Member of Supply Chain Subcommittee, Global Compact Network Japan.

- Japan Food Service Association Food Procurement and Development Supervisory Committee