Skylark Group Procurement Policy

To realize the management philosophy of "Creating Richness with Value to Society", we believe it is important to meet the requirements of laws and regulations, and continuously provide safe and secure products to "provide valuable richness” through “food service” to our customers, which is an important responsibility of Skylark Group.

In order to earn the trust of our stakeholders, we ask our suppliers to understand and practice the following items regarding respect for human rights and global environmental conservation. We aim for coexistence and co-prosperity with our suppliers in our corporate activities and social and environmental responsibilities.

- Suppliers shall only provide safe products that meet the Food Sanitation Law of Japan and other related laws and regulations, and quality standards of the Company. Also, suppliers shall understand and cooperate with the inspection and audit of their manufacturing process of their products that the Company requests.

- In addition to providing only those products that pass bacterial tests conducted by our company, suppliers shall cooperate in providing information on food safety and quality required by the Company, including reports from external organizations regarding residual pesticides.

- Suppliers shall respect the human rights of their employees and will not treat them inhumanely.

- Suppliers shall prevent forced labor and child labor in their employees, eliminate excessive working hours in violation of laws and regulations, and secure minimum wage.

- Suppliers shall not engage in employment discrimination.

- Suppliers shall respect the freedom of association of employees and the right to collective bargaining in order to facilitate smooth discussions between labor and management.

- Suppliers shall strive to provide employees with a safe, hygienic and healthy working environment.

- Suppliers shall comply with relevant domestic and foreign laws and regulations. Suppliers shall also ensure compliance to fair transactions and anti-corruption.

- Suppliers shall emphasize the sustainability of natural resources and strive to conserve resources, and minimize the use of non-renewable resources. Natural resources obtained through illegal trade, extraction, or fishing shall not be used.

- Suppliers shall endeavor to understand and cooperate with our policy on biodiversity, animal welfare, energy saving, renewable energy, water conservation, food loss reduction, waste reduction, climate change, CO2 / GHG emission reduction, etc. Also, suppliers shall endeavor to understand and cooperate with the Company regarding communication, information provision, training, etc. regarding various issues.

- Suppliers shall provide and disclose information regarding all items above in a timely and appropriate manner.

January 13, 2021

Approved by Group Sustainability Committee

Cases of Material Breach

In the event of a material breach relating to this policy, we shall, upon verifying the facts, request that the supplier improve the situation. We ask all suppliers and secondary suppliers to be aware of and thoroughly adhere to the CSR Procurement Guidelines. If necessary, we or our designated experts will visit the site and conduct investigation. In addition, if no improvement has been made after a specified period, we will take measures which may include a reconsideration of the contract with the supplier or business partner.

Promoting Responsible Procurement

To fulfill social responsibilities through our business operations, Skylark Group has established purchasing management regulations, through which we ensure the purchase of safe, high-quality ingredients and respond to social issues, in addition to complying with laws and regulations.

When selecting suppliers, we check not only financial reliability and consistency of quality but also employee management by suppliers (ensuring occupational safety and health), consideration for human rights (preventing child labor, forced labor, discrimination and long working hours; right to freedom of association and collective bargaining), consideration for the environment (conserving energy, mitigating climate change, protecting water resources and biodiversity, preventing food loss and using resources efficiently), and other antisocial activities. We prioritize the selection of suppliers who are fulfilling their responsibilities to society.

We also ask suppliers for their understanding and cooperation in providing information relating to our environmental policies, communication with our company and training activities, to engage in joint corporate activities and aim for coexistence and co-prosperity of society and the environment together.

Currently, we have suppliers in 40 countries around the world. We do not judge based on the local laws, customs, and conditions of each region, but rather on whether there are any significant discrepancies when benchmarked against international standards. We strive for responsible procurement by enforcing a strict policy of not initiating transactions if any problems are found.

1. Supplier Selection

When selecting new suppliers, we conduct the following due diligence on all suppliers prior to the start of transactions in accordance with our "Detailed Rules for Sustainable Procurement Management" for the purpose of risk assessment of environmental and social issues.

In our supplier selection process, we have introduced a methodology to consider and evaluate the following sustainability risks:

- Country-specific risks: We consider the risk of negative ESG impacts related to the political, economic, environmental, and regulatory conditions in the countries and regions where the supplier operates.

- Sector-specific risks: We consider the risk of negative ESG impacts related to labor conditions, emissions, and pollution within the sector to which the supplier belongs.

- Product-specific risks: We consider the risk of negative ESG impacts related to the supply chain structure, labor conditions, energy consumption, emissions, and pollution of the procured products.

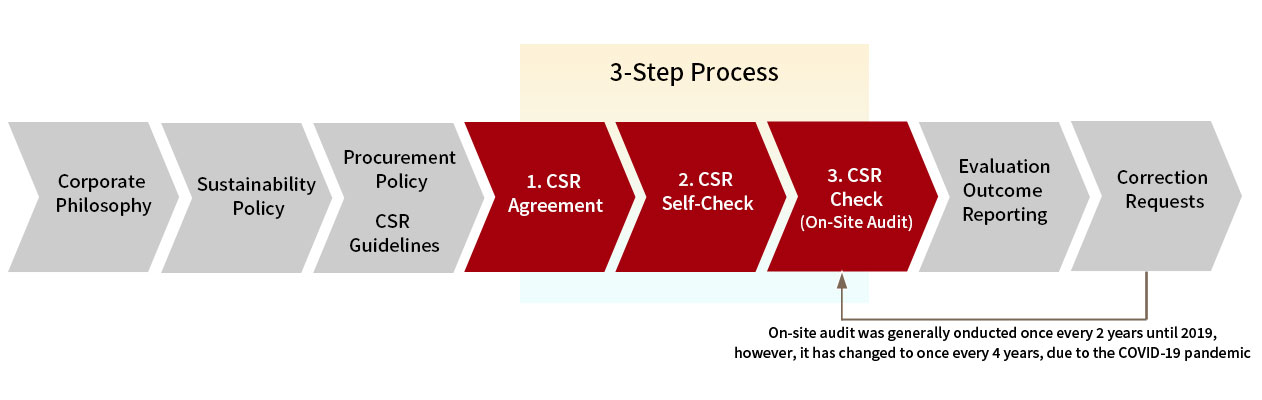

Due Diligence Process

- CSR Agreement: Process to request suppliers to agree to our procurement guidelines before starting business with us.

- CSR Self-check: Process to assess suppliers' understanding of CSR requirements by asking them to complete a self-assessment.

- CSR Check: A process where our buyers visit supplier factories directly to assess current conditions in collaboration with suppliers, and utilize the results for improvement activities. Based on a CSR checklist, we mutually check with the supplier on the implementation status of requirements and share best practices.

*This also applies to secondary suppliers.

*Supplier evaluations are conducted with reference to the methodology of the Global Compact Network Japan's supply chain subcommittee.

Scope of coverage

2. Supplier Monitoring and Audit