Policy and Approach

To fulfill social responsibilities through our business operations, Skylark Group has established purchasing management regulations, through which we ensure the purchase of safe, high-quality ingredients and respond to social issues, in addition to complying with laws and regulations. In addition, the "Group Sustainability Committee" meets as needed and continues to formulate policies, targets, and measures related to responsible procurement.

In selecting suppliers, we prioritize those that are making meaningful progress in environmental, social, and governance (ESG) practices by incorporating ESG criteria that go beyond financial reliability and product quality. Our evaluation includes a wide range of factors, such as employee management to ensure occupational health and safety, as well as respect for human rights through the elimination of child labor and forced labor, the prevention of discrimination and harassment, and the protection of freedom of association, collective bargaining, and the prevention of excessive working hours. Furthermore, we consider environmental responsibility, covering energy use, climate change response, pollution prevention, waste and water management, biodiversity, food loss reduction, and resource utilization, alongside ethical compliance regarding anti-corruption, management of conflicts of interest, and prevention of anti-competitive behavior. We also take into account the supplier's status regarding any other forms of antisocial conduct.

Moreover, we encourage our suppliers to implement and obtain certification for environmental management systems such as ISO 14001. In line with this, we require compliance with our expectations, which include reducing raw material consumption, tracking greenhouse gas emissions, reducing the use of hazardous substances, and ensuring the proper treatment of hazardous waste and harmful atmospheric emissions.

We also ask suppliers for their understanding and cooperation in providing information relating to our environmental policies, communication with our company and training activities, to engage in joint corporate activities and aim for coexistence and co-prosperity of society and the environment together.

Currently, we have suppliers in 40 countries around the world. We do not judge based on the local laws, customs, and conditions of each region, but rather on whether there are any significant discrepancies when benchmarked against international standards. We strive for responsible procurement by enforcing a strict policy of not initiating transactions if any problems are found.

1. Supplier Selection

When selecting new suppliers, we conduct the following due diligence on all suppliers prior to the start of transactions in accordance with our "Detailed Rules for Sustainable Procurement Management" for the purpose of risk assessment of environmental and social issues.

In our supplier selection process, we have introduced a methodology to consider and evaluate the following sustainability risks:

- Country-specific risks: We consider the risk of negative ESG impacts related to the political, economic, environmental, and regulatory conditions in the countries and regions where the supplier operates.

- Sector-specific risks: We consider the risk of negative ESG impacts related to labor conditions, emissions, and pollution within the sector to which the supplier belongs.

- Product-specific risks: We consider the risk of negative ESG impacts related to the supply chain structure, labor conditions, energy consumption, emissions, and pollution of the procured products.

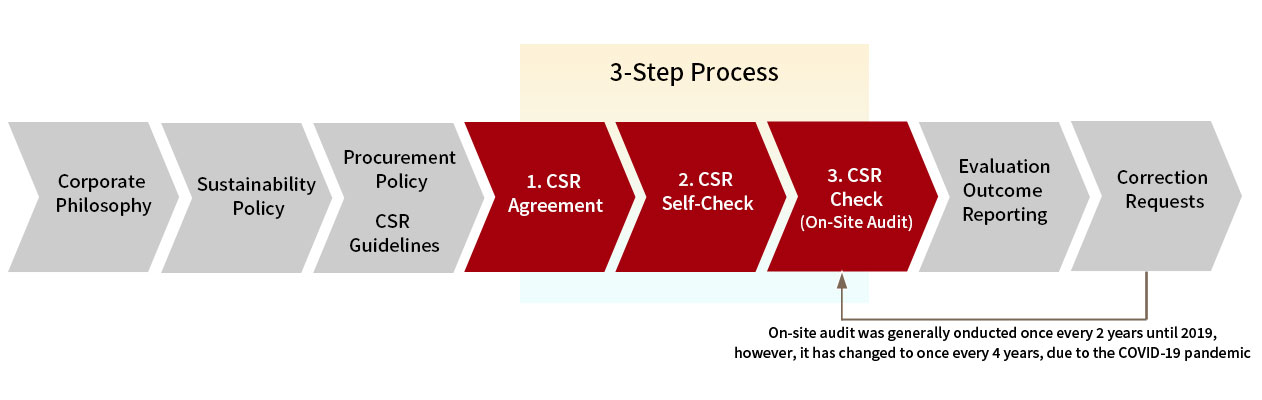

Due Diligence Process

- CSR Agreement: Process to request suppliers to agree to our procurement guidelines before starting business with us.

- CSR Self-check: Process to assess suppliers' understanding of CSR requirements by asking them to complete a self-assessment.

- CSR Check: A process where our buyers visit supplier factories directly to assess current conditions in collaboration with suppliers, and utilize the results for improvement activities. Based on a CSR checklist, we mutually check with the supplier on the implementation status of requirements and share best practices.

*The scope of these monitoring and audit activities is not limited to direct (Tier 1) suppliers but also extends to certain upstream Tier 2 suppliers, as we strive to mitigate risks across the entire supply chain.

*Supplier evaluations are conducted with reference to the methodology developed by the Supply Chain Subcommittee of the Global Compact Network Japan.

Scope of Coverage

2. Supplier Monitoring and Audit

- We regularly monitor and audit all suppliers, regardless of their location or transaction volume, with the goal of covering each supplier once every two years. Through this process, we identify environmental and social risks and specify suppliers with high-risk profiles. Furthermore, we provide feedback on the results to all suppliers, offering support that includes information sharing and guidance for improvement.

- Under the supervision of the Board of Directors, the status and details of our monitoring and auditing activities are reported quarterly to the Group Sustainability Committee to promote these initiatives. The committee is chaired by the President and COO, and its members include the Chairman and CEO, all Executive Officers, and the presidents of Group companies.

- Since fiscal 2022, in addition to our conventional monitoring of food and product quality and safety, we have conducted monitoring, audits, and training to evaluate risks. This includes evaluating risks related to social issues such as human rights, labor practices, and fair business activities based on our "Procurement Policy" and "Anti-Bribery and Anti-Corruption Policy," as well as evaluating their fundamental stance and risks concerning environmental initiatives based on our "Environmental Policy."

- We hold meetings with our suppliers at least once a year to engage in risk-conscious communication and provide guidance on environmental and social issues based on our "CSR Guidelines."

- Our buyers regularly visit all supplier manufacturing plants—not only at the start of a new transaction but also periodically thereafter—to verify that their food safety processes are operating as intended and to provide evaluation and guidance. The results are documented, stored, and shared with the supplier to facilitate continuous improvement.

- For each supplier, we conduct a quantitative confirmation of changes in transaction volume and the results of food hygiene inspections, sharing this information with our finance and quality management departments.

- Our on-site audits and evaluations go beyond food hygiene inspections to include risk assessments for occupational health, safety, and environmental conservation.

- Buyers are responsible for gathering as much information as possible on supplier practices concerning employee management, respect for human rights, pollution control measures, and any potential involvement in anti-social activities.

- For overseas suppliers, assessments are not based solely on local laws, customs, and conditions. Rather, the responsible manager at our headquarters conducts an evaluation by benchmarking the supplier’s practices against international standards, based on a confirmed report.

- We evaluate the corporate reliability of our suppliers based on documents provided by the suppliers and publicly available information, taking into account both industry-specific information and sector-specific risks against our internal standards. Following on from fiscal 2022, 2023, and 2024, there were no instances of supplier non-conformance with our "Environmental Policy," "Procurement Policy," or "Anti-Bribery and Anti-Corruption Policy" in fiscal 2025. Should non-conformance or a serious violation occur, we will confirm the facts and require the supplier to take corrective action. If necessary, our company or a designated specialist will conduct an on-site investigation. If improvements are not made within the required timeframe, we will take further measures, including a review of our business relationship.

- We have established a dedicated whistleblowing contact point for business partners that is accessible to supplier employees, and we are promoting awareness of this resource among our suppliers through CSR checks and other initiatives.

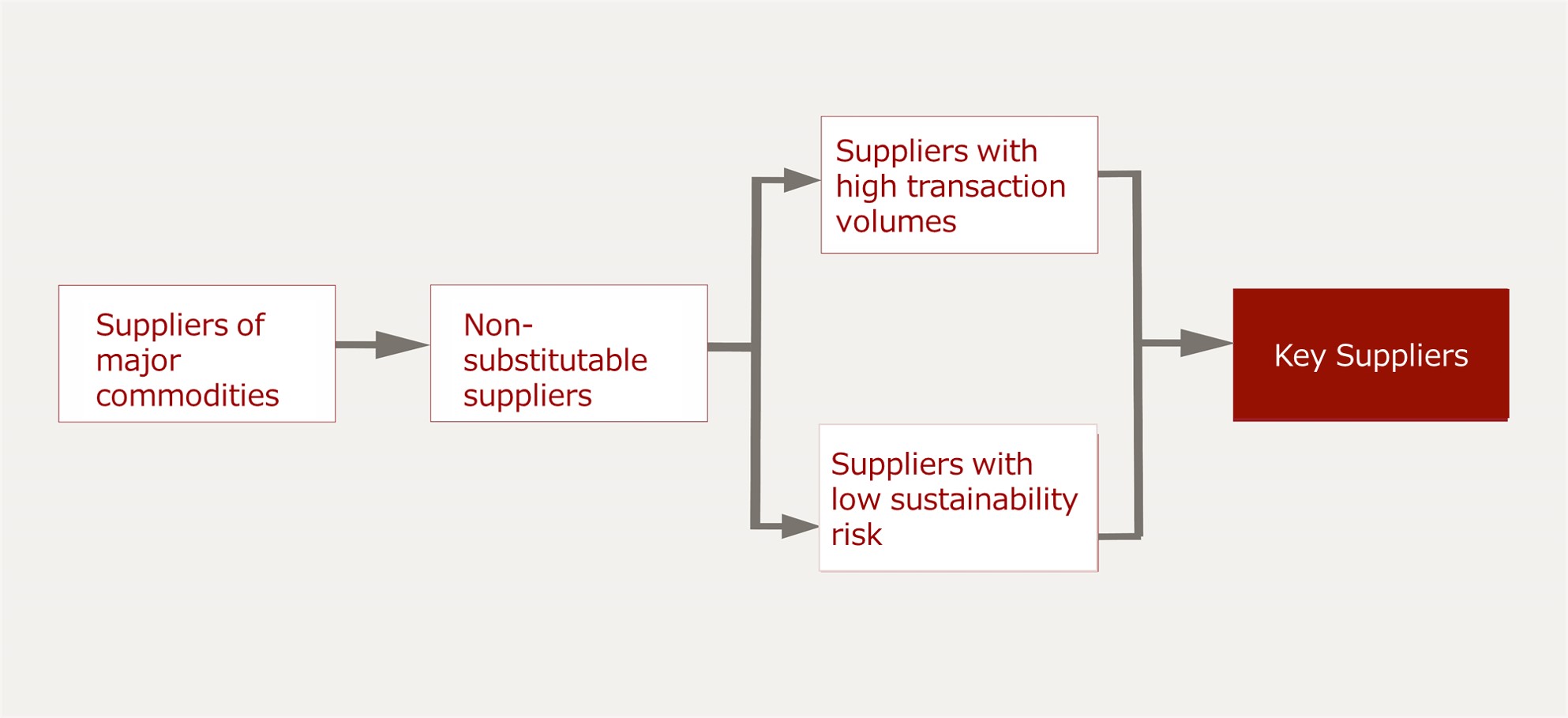

- We continuously disclose the management status of our key suppliers, who are identified based on transaction volume and ESG risks. As a key indicator, we disclose information on this page such as the percentage of transaction value from these key suppliers (63.1%), and we remain committed to expanding our information disclosure to further enhance transparency.

- ※1 Suppliers identified as having an impact on ESG, or having high business relevance and risk.

- ※2 Suppliers provided with opportunities for knowledge sharing and communication to promote sustainable procurement.

Key Suppliers

Suppliers identified as having ESG impacts or high business relevance and risk.

| Item

|

Definition

|

| Suppliers of major commodities |

Products with annual value of 1 billion yen or more and suppliers handling 500 million yen or more |

| Non-substitutable suppliers |

Purchases of 500 million yen or more per item and PB items |

| Suppliers with high transaction volumes |

Business partners with high transaction volume (transaction value of 1 billion yen or more) |

| Suppliers with low sustainability risk |

Suppliers that have been assessed for sustainability risks (including country, region, sector, and product category) and have been determined to have a CSR check score of 95 or higher. |

Specific Process

3. Education and Training for Skylark Buyers

- Joint training sessions are held twice a year for all buyers to acquire and update knowledge in line with revisions of laws and regulations and changes in social conditions, and through the guidance of the in-house quality control department, education is provided.

- We also conduct on-the-job verification through "training programs accompanying" existing buyers' quality control staff when they visit suppliers in Japan and overseas.

- At the time of buyer's arrival, "Basic Knowledge Acquisition" including factory and sanitation center training is conducted based on a prescribed curriculum.

- Procurement Department employees comply with laws and regulations, industry agreements and norms, strive to gather information from the relevant ministries, agencies, industry bodies and suppliers; share with related departments within the company, including the Quality Control Department; and establish and revise management methods.

- We are fully aware that our contracts with suppliers are based on "fair, reasonable, and transparent" business relationships and that we are in a "superior position" in the eyes of society, and we strive to avoid any misunderstanding that we are engaged in "unfair" business relationships.

- Training for Skylark buyers on environmental and social issues is conducted at least twice a year.

4. Support for Initiatives and Cooperation with External Organizations

- To help realize a sustainable society, our company actively collects advanced information from initiatives and consortiums both in Japan and abroad. In addition, to reduce the environmental impact of our supply chain, we participate in industry- and theme-specific initiatives and promote efforts based on their guidelines. Through activities in cooperation with suppliers and companies in other industries, we aim to reduce the Group's overall environmental impact and resolve social issues.

(Initiatives to reduce environmental impact and tackle societal issues)

- ISO 20400, the international standard for sustainable procurement

Foodstuff procurement operations in 18 categories under the jurisdiction of the Foodstuff Purchasing Group, and other operations as per "Details of Compliance with Certification/Registration (Details)".

- United Nations Global Compact, and Member of Supply Chain Subcommittee, Global Compact Network Japan.

- Japan Food Service Association Food Procurement and Development Supervisory Committee

- Japan Climate Initiative (JCI)